- Replies 127

- Views 10.3k

- Created

- Last Reply

Most active in this topic

-

boba 30 posts

-

Pete Eccles 14 posts

-

Amsterdam Russ 9 posts

-

Mace 7 posts

Most Popular Posts

-

Alternatively, you could purchase the strongest, most potent glue on the market. Fill a small bag, and inhale fumes for 20 minutes. Record will then soun

-

Well that's of no consequence in this issue cus it sound like the record in question is fcuked anyway. As is the record deck, shortly followed by Bobs toothbrush by the sound

-

Got to be a serious contender for thread of the year.....

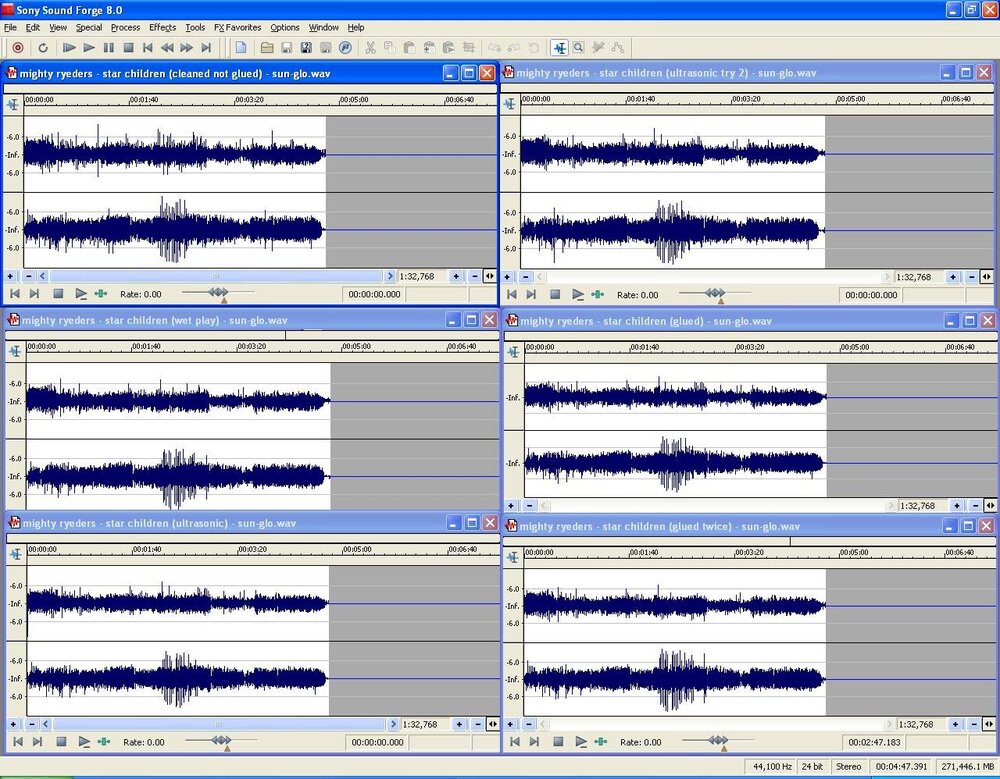

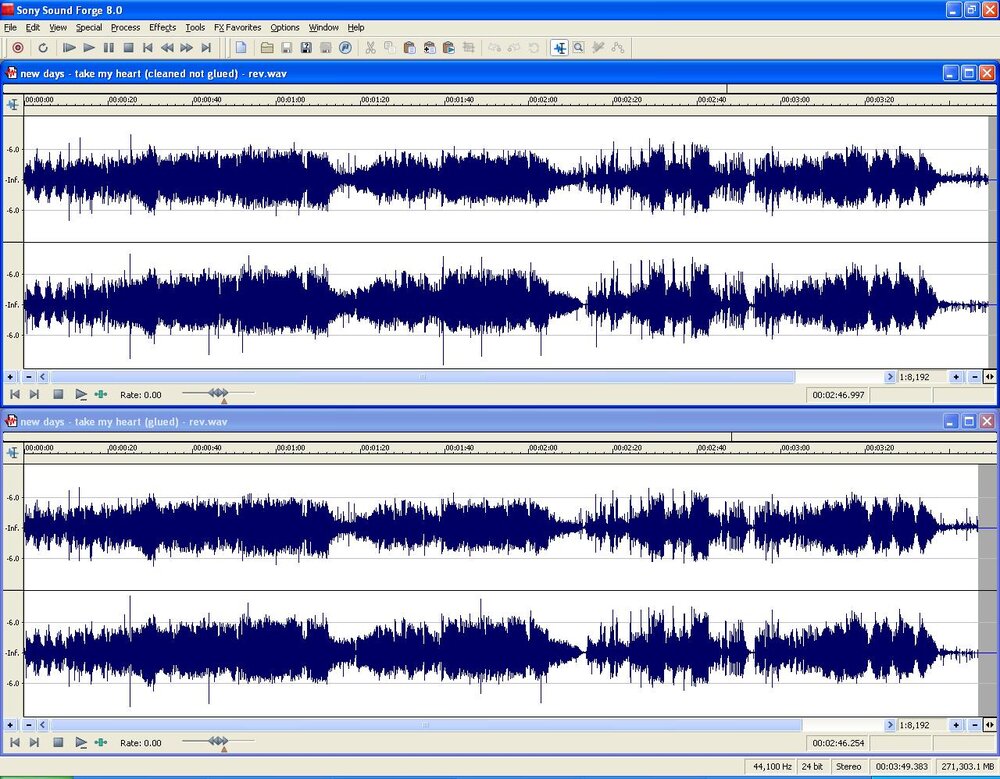

so yesterday I cleaned a 45 and it still played extremely crackly, despite not really being scratched up very much. The main reason was because it was almost 5 minutes long, which means it was pressed at a lower volume making the crackles overwhelm the music. However, it still looked clean enough to me that it should have been playing better. I decided to try the glue thing. I know this is not an ideal situation because it's probably scratches and the pressing and not dirt that's making it sound bad, but I can clean a 45 well enough that it's rare that it plays worse than it looks... so this is one of the best opportunities I could come up with

I made a recording of the record after I cleaned it but before applying any glue. I only had the elmers glue-all (which is not the yellow wood glue that was recommended to me in the previous thread). I put the record on my turntable and squeezed the glue on, moving it from the inner deadwax to the outside slowly as it rotated. I then used a credit card to spread the glue all over the record and into the grooves. I couldn't keep the glue from going over the edge of the record but fortunately it didn't go farther into the deadwax and get to the label. I also found it was hard to apply the glue evenly, even if I put more glue on the record, so it clearly was thicker in some places than others (and you could see the black of the vinyl coming through some places but not othes). This is what it looked like last night after applying the glue:

today the 45 is glued to the turntable mat, I have not tried to remove it or the glue from the record yet. What is annoying is that some of the drips of glue that are on the mat don't come off easily, I hope I can get the glue off the record. I'm just about to do try to remove the glue, will report back.